OPC Drum Introduction

Basic Principle

-

Copy machine

-

Cartridge

-

OPC drum

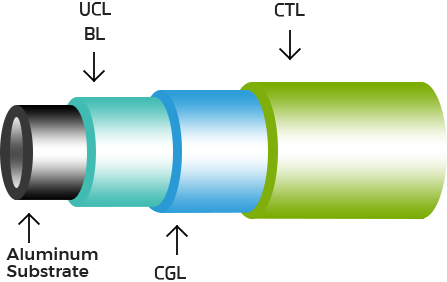

Configuration

An ordinary OPC drum typically consists of a multi-layer structure. The Charge Generation Layer (CGL) is composed of charge-generating materials (CGM) and a polymer resin (CG-Binder), while the Charge Transfer Layer (CTL) comprises charge transfer materials (CTM) and a polymer resin (CT-Binder). This layered structure enables the OPC drum to exhibit a negative charge on its surface, known as the reverse charging method. This configuration is advantageous for high sensitivity and high-speed laser printers. Alternatively, there is a single-layer structure where the Charge Generation Layer (CGL) and Charge Transfer Layer (CTL) are combined into one photosensitive layer. In this case, an electron transfer material (ETM) is added to construct the OPC drum, and the drum surface exhibits a positive charge, known as the direct charging method. This configuration has the advantage of being able to produce a large volume of prints.

| OPC Product | ||

|---|---|---|

| OPC | CGM (Gamma, Alpha,Metal free) | CG-01H, CG-01L, CG-02 |

| CTM(TPD, Stillbene, Hydrazone, Butadiene, Other) | CT-100T, CT-101T, CT-102T, CT-103T, CT-104 CT-202S, CT-203S CT-304H, CT-313H CT-403B |

|

| ETM | ET-102,ET-202 | |

| CT-binder | PC-300, PC-500 | |

| TPA (anti-crack agent) | AC-102, AC-103 | |